section-c19f3b5

section-a997800

The labeling and printing of components is one of the common work steps that are regularly requested in the course of production. We offer two proven techniques in our production facility:

section-204c466

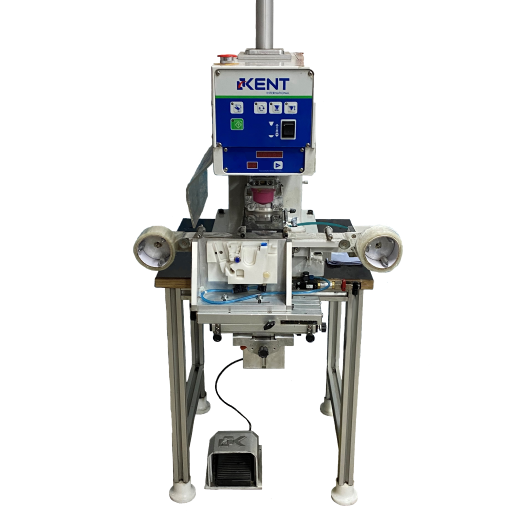

The Pad Printing

Pad printing is one of the most important techniques for printing on plastic parts. But metal, glass and ceramics are also used as printing substrates. By using an elastic pad as a printing tool, almost any shape can be printed. Due to the high printing quality and color saturation, the process is used across all industries. Amongst others on tools, electrical appliances, fittings, toys, household and sports articles.

section-3dbac9f

Laser Marking

In contrast to conventional printing, laser marking does not apply color to the material to be printed. Instead, a pulsed fiber laser directly changes the material. This makes the laser marking water and smudge-proof and very durable. In addition to industrial applications, laser markings are increasingly used in the advertising and present article industry. The laser technology is universally applicable and is suitable for hardened or coated metals, alloys or other coated materials in addition to plastics. In addition, even very small markings and labels can be applied.